In today’s industrial world, effective waste management is not just about disposal—it’s about optimization, recycling, and sustainability. Shredders play a pivotal role in this transformation. From reducing bulky waste to preparing materials for recycling, industrial shredders are a core component in facilities across manufacturing, construction, and environmental sectors.

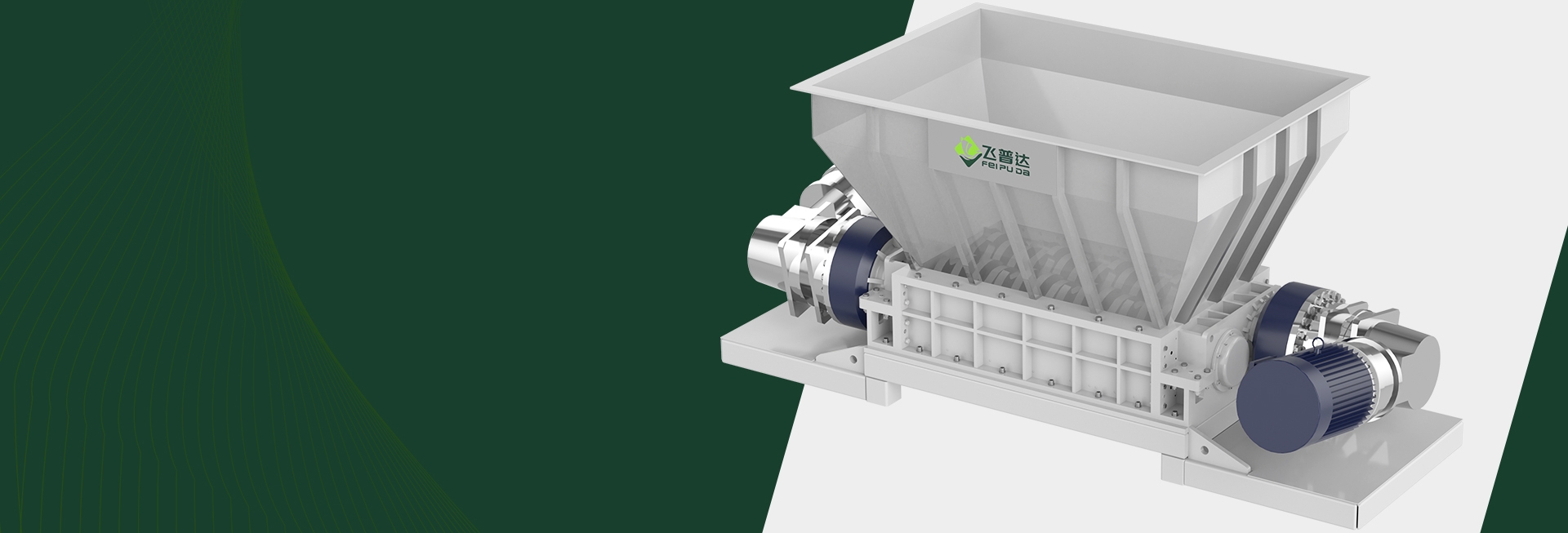

A double-shaft shredder, sometimes called a twin-shaft shredder, is a heavy-duty industrial machine designed to tear through large volumes of tough materials using two synchronized cutting shafts. Unlike single-shaft or four-shaft machines, double-shaft shredders prioritize power and durability, making them perfect for shredding hard-to-break-down materials like metals, tires, and electronics.

| Type | Shaft(s) | Ideal For | Cutting Mechanism |

|---|---|---|---|

| Single-Shaft | 1 | Uniform plastics, paper | Rotary cutting against a fixed blade |

| Double-Shaft | 2 | Heavy, bulky, and mixed materials | Intermeshing dual cutters |

| Four-Shaft | 4 | Small granules or secondary shredding | Dual-stage precision shredding |

These shredders operate using two parallel rotors, each equipped with cutting discs that rotate slowly but with high torque. As materials are fed into the hopper, the twin shafts grab and pull them into the machine, slicing and tearing them apart through sheer force.

Slow-Speed, High-Torque: This minimizes heat and dust while maximizing force.

Counter-Rotating Shafts: Ensures continuous grip on the material, reducing jamming.

Self-Cleaning Action: The intermeshing blades help reduce clogging and ensure consistent operation.

Modern double-shaft shredders are engineered for rugged, long-term operation. Core features include:

Dual Rotors: Balanced and precisely aligned for optimal cutting force.

High Torque Electric or Hydraulic Motors: Powerful enough to handle dense and abrasive materials.

Hardened Steel Blades: Wear-resistant and easily replaceable.

Smart Control Systems: Monitor torque, pressure, and motor load to prevent overloading.

One of the standout features of double-shaft shredders is their versatility in handling a wide range of input materials:

Metals: Aluminum, copper, steel sheets, etc.

Plastics: Pipes, crates, drums, and more.

Tires: Passenger, truck, and industrial tires.

E-waste: Printed circuit boards, cables, appliances.

Wood: Pallets, logs, crates.

This makes them indispensable in multi-material recycling centers and heavy industrial sites.

These machines are built for volume, capable of processing tons of material per hour.

Fewer moving parts and robust design mean less downtime and lower long-term costs.

With customizable blade configurations and variable speed drives, they can be tuned to suit specific waste streams.

By enabling efficient waste reduction and material reuse, double-shaft shredders support eco-conscious operations.

| Feature | Double-Shaft | Single-Shaft |

|---|---|---|

| Cutting Power | High (suitable for tough materials) | Moderate (best for lighter materials) |

| Material Handling | Mixed, bulk, hard-to-process items | Homogeneous materials only |

| Maintenance | Less frequent | More frequent |

| Application Scope | Broader industrial and recycling uses |

Narrower, mostly plastics |

Double-shaft shredders are widely used across multiple industries due to their robust performance and ability to process various materials. Here are the most common application areas:

Local governments and waste authorities use double-shaft shredders to process bulky waste like furniture, mattresses, and household appliances. This allows for easier landfill compaction or recycling.

In the auto industry, shredders are vital for breaking down car bodies, bumpers, and tires into manageable sizes for further sorting and metal recovery.

These machines easily handle wood, insulation, plastic pipes, and even light metals found in construction debris, enabling better resource recovery and reduced environmental impact.

Manufacturers of plastic products or rubber items often use these shredders to reduce production scrap or recycle post-consumer waste.

Shredders play a key role in dismantling electronics, separating valuable components, and safely disposing of hazardous materials.

Safety is non-negotiable in industrial environments. Double-shaft shredders are engineered with built-in protections to safeguard operators and meet industry regulations.

Emergency Stop Buttons: Instantly halt operation during anomalies.

Overload Sensors: Prevent motor damage by pausing operations when capacity is exceeded.

Interlocked Doors: Machine halts automatically if safety doors are opened.

High-quality shredders, like those from Fipda, typically comply with CE, ISO 9001, and other global safety certifications, ensuring peace of mind during continuous operations.

While double-shaft shredders can represent a significant upfront investment, their long-term return often outweighs the cost. Here’s why:

| Cost Factor | Impact on ROI |

|---|---|

| Initial Equipment Cost | Higher than single-shaft models, but more durable |

| Operational Efficiency | Lower energy usage per ton processed |

| Maintenance | Less frequent blade replacements and downtime |

| Material Savings | Enables recycling of raw materials, reducing procurement costs |

By investing in a durable and efficient shredder, businesses can save money on waste disposal, reduce environmental fees, and generate new revenue from recycled materials.

To ensure a long and productive lifespan for your double-shaft shredder, follow these key maintenance practices:

Lubricate Bearings and Gears: Keeps all moving parts running smoothly.

Inspect Blades for Wear: Replace or sharpen when cutting performance drops.

Check for Unusual Noises: Could indicate loose parts or overloading.

Monitor Motor Load: Helps detect processing inefficiencies or mechanical issues.

Always operate the shredder within specified load limits.

Use OEM parts to maintain system integrity.

Train operators on safe and efficient usage.

A well-maintained shredder not only reduces repair costs but also boosts daily productivity.

Industrial shredders aren’t just about waste destruction—they’re also tools for sustainability.

By shredding materials for reuse or recycling, these machines support resource conservation and lower dependence on virgin raw materials.

Shredded waste is more efficient for incineration or biogas generation, making it a key step in WTE facilities.

Volume reduction minimizes landfill strain, helping cities and industries meet waste reduction goals.

The next generation of double-shaft shredders is smarter, faster, and more energy-efficient.

Real-time performance tracking, automatic alerts for maintenance, and remote diagnostics enhance uptime and safety.

Some machines adjust blade speed and torque based on the material density, improving efficiency and prolonging blade life.

Integrated conveyor systems ensure consistent feeding, reducing the need for manual labor and preventing jamming.

Not every shredder fits every operation. Consider these factors when selecting the right machine:

| Factor | Why It Matters |

|---|---|

| Material Type | Affects blade selection and motor capacity |

| Throughput Volume | Determines size and power requirements |

| Physical Space | Check machine footprint vs available area |

| Noise Restrictions | Low-noise models may be required for indoor or urban use |

| After-Sales Support | Reliable service reduces downtime and repair costs |

Partnering with an expert supplier like Fipda ensures you get a machine tailored to your needs.

Fipda is a leader in sustainable waste processing technologies. They offer a range of shredding solutions backed by years of R&D and global certifications.

Innovative Designs: Machines tailored for performance and durability.

Reliable Support: Expert teams for installation, training, and maintenance.

Sustainability Focus: Technologies that align with green initiatives.

Explore their full lineup of industrial shredders here.

Stay updated with the latest from the shredding and recycling world on Fipda's news page. Topics include:

Emerging trends in waste-to-energy.

Smart manufacturing for recycling plants.

Shredder technology updates and safety protocols.

Double-shaft shredders can process metals, plastics, tires, wood, e-waste, and more.

It uses two intermeshing shafts for more aggressive, high-torque cutting—ideal for tough and mixed materials.

Yes. Lubrication, blade checks, and motor monitoring are key to long-term reliability.

Absolutely. It’s widely used in recycling plants to downsize materials for sorting and reuse.

Waste management, automotive recycling, plastic manufacturing, construction, and municipal services.

Fipda offers industrial-grade shredders tailored to specific needs, along with comprehensive support services.

Double-shaft shredders are more than just powerful machines—they’re a strategic asset for industries aiming to manage waste efficiently, reduce environmental impact, and improve operational productivity. With their high torque, versatility, and rugged design, they offer a long-lasting solution for even the toughest shredding challenges.

If you're ready to streamline your waste processing and make an eco-friendly choice, explore the premium range of shredders from Fipda and stay informed with their latest updates.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China