Welcome to the world of serious slicing—where it’s not just about breaking things down, it’s about breaking them down right. Whether you're managing kitchen waste from a bustling cafeteria or recycling plastics from an industrial site, choosing between a single or double-shaft shredder could make—or shred—your efficiency.

Let’s cut through the confusion. (Pun fully intended.)

Choose the wrong shredder and you’re looking at jammed blades, skyrocketing energy bills, uneven particle sizes, and enough noise to rattle the neighborhood.

Industrial clients want power, precision, and output volume. Kitchen waste managers need sanitary processing, odor control, and equipment that doesn’t flinch at fibrous food or bones.

A single-shaft shredder uses—you guessed it—one rotating shaft with cutters that push material through a screen. It’s best for lighter-duty or pre-sorted materials like plastic film, rubber, or wood.

Great for:

Plastic containers

Foam

Wood scraps

Not-so-great for:

Mixed waste

Wet materials

Tough industrial debris

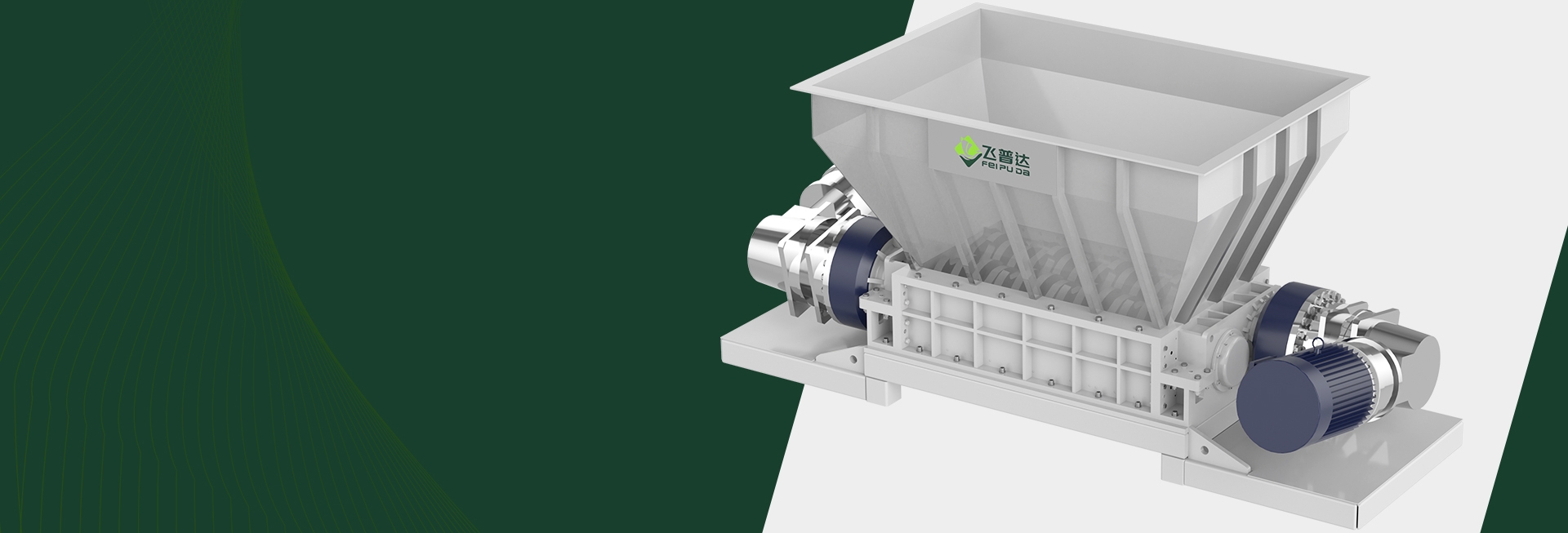

This beast uses two counter-rotating shafts to tear, shear, and shred nearly everything you feed it. Think car bumpers, kitchen waste, metal drums—you name it.

With more torque and synchronized power, double-shaft shredders are the go-to for industrial throughput, durability, and minimal jamming.

Learn more here: What Is a Double-Shaft Shredder?

| Feature | Single-Shaft | Double-Shaft |

|---|---|---|

| Torque & Power | Lower | High torque |

| Material Type | Dry, sorted | Mixed, wet, industrial |

| Output Consistency | Smaller, even | Variable sizes |

| Energy Efficiency | Better for small-scale | Powerful but power-hungry |

| Maintenance | Easier to clean | Heavy-duty parts |

| Noise Levels | Lower | Louder (but manageable) |

Short answer? Double-shaft—especially for kitchen waste with:

High moisture

Fibrous skins

Animal bones

But in smaller kitchens or cafeterias, a compact single-shaft might do the trick if the input is pre-sorted and soft.

No contest—double-shaft wins for:

Textile recycling

Scrap metal processing

Electronic waste

Its raw power and design allow continuous operation and bulk volume reduction.

A Chinese city used our double-shaft model to process 2.5 tons/hour of mixed food waste. Result? Reduced volume by 70% and odor complaints dropped to zero.

One textile plant struggled with tangled, bulky fabric rolls. Our solution: a double-shaft shredder with serrated blades. Problem solved, recycling boosted.

See more: FPD Green Projects

Torque sensors to prevent overload

AI-monitored shredding behavior

Modular cutter replacement for specific waste streams

Future-ready? Absolutely.

Single-shaft units: Lower up-front cost, ideal for light usage

Double-shaft: Higher initial price, but less downtime and higher output = ROI in less than 12 months

What’s the daily volume you process?

Are your materials moist, dense, or fibrous?

Do you need batch or continuous processing?

How important is maintenance access?

Do you require custom output sizes?

We’re FPD GREEN—leaders in sustainable shredding solutions for kitchen, municipal, and industrial clients worldwide.

Explore our machines: FPD Shredder Lineup

Ask us anything: FPD FAQ Page

Q: Which is easier to maintain?

Single-shaft. Fewer parts, quicker clean-up.

Q: Can I switch blade types?

Yes! FPD offers modular blades for both.

Q: Is one more eco-friendly?

Double-shaft units often save more on landfill space but use more energy.

Q: How noisy are these machines?

Single-shaft is quieter, but FPD adds insulation and mufflers for both types.

Q: Which is safer for smaller operations?

Single-shaft offers more basic safeguards; double-shaft needs trained operators.

Go single-shaft if you’re dealing with dry, uniform waste in lower volumes.

Go double-shaft if you need to crush, tear, and dominate the trash game.

Want help picking? Talk to the pros: FPD Green

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China