The conveyor is mainly composed of casing, bottom frame, wear-resistant liner, shaftless screw body, K series gear motor, electro-hydraulic gate and electric control system.

For the center distance between inlet and outlet is less than 7 meters, it adopts one-stage conveying, and for more than 7 meters, it adopts two-stage conveying.

1. Main components and related parameters

|

Equipment Name |

Drain Screw Conveyor |

Drain Screw Conveyor |

Shaftless Screw |

Shaftless Screw |

Shaftless Screw |

Shaftless Double Screw conveyor

|

|

Model |

WLS400-L |

WLS500-L |

WLS300-L |

WLS400-L |

WLS500-L |

2*WLS500-L |

|

Conveyor length |

Length L is customized (generally less than 12 m) |

|||||

|

Screw diameter (mm) |

400 |

500 |

300 |

400 |

500 |

500 |

|

Rated power (Kw) |

11-15 |

11-15 |

4-11 |

5.5-15 |

7.5-15 |

2*(11-15) |

|

Maximum speed (r/min) |

25 |

25 |

25 |

25 |

25 |

25 |

|

Blade material |

Wear-resistant manganese steel or stainless steel |

|||||

|

Drive mode |

Motor reducer direct drive |

|||||

|

Control mode |

Industrial frequency |

|||||

|

Noise (dB) |

≤70 db |

|||||

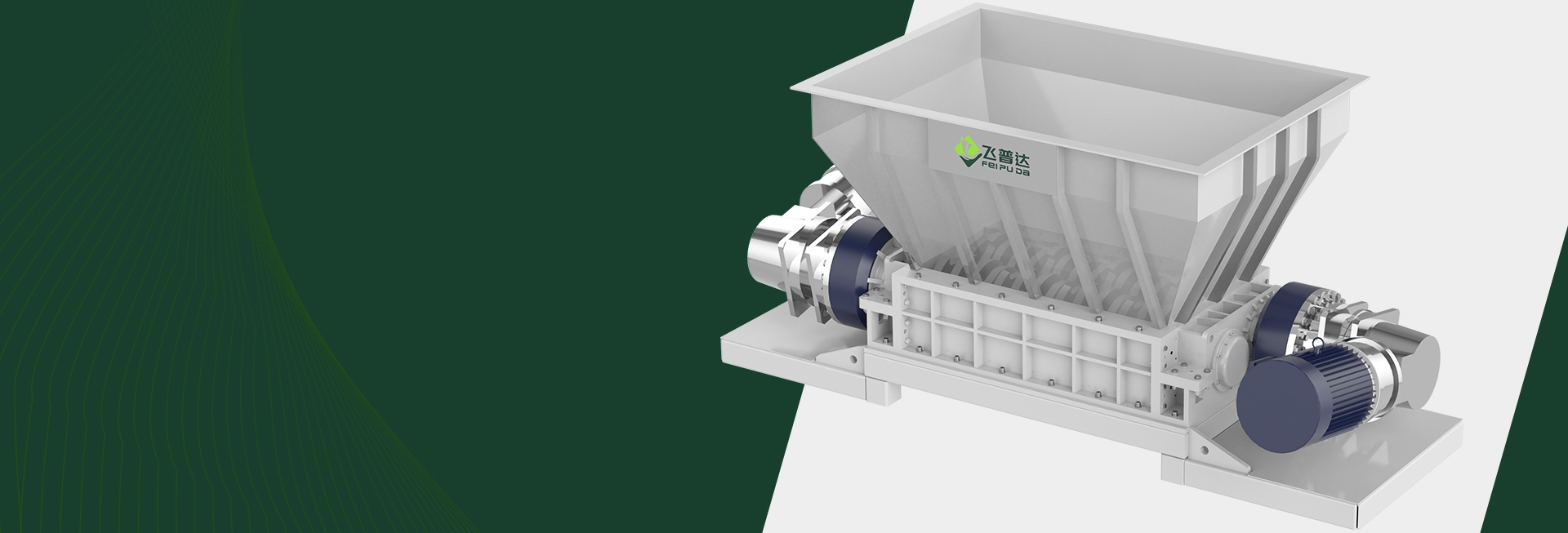

2. Characteristics of WLS type shaftless screw conveyor

1) Using the design of no center shaft, it has special superiority for conveying belt-shaped and easy-to-tangle materials, with strong anti-tangle.

2) Using low speed, high torque, low power frequency conversion speed reducer, low energy consumption.

3) Good environmental performance, the use of fully enclosed conveyor and easy to clean the spiral surface, can ensure environmental health and the conveyed materials do not leak.

4) The blade adopts trapezoidal type to strengthen the design, which increases the rigidity of the spiral body and is suitable for large torque conveying.

5) Compact structure, space-saving, easy to operate, beautiful appearance.

6) Length, size, speed can be customized according to the demand and adaptability.

3. Structure of WLS type shaftless screw conveyor

For the center distance between inlet and outlet is less than 7 meters, it adopts one-stage conveying, and for more than 7 meters, it adopts two-stage conveying.

The conveyor is mainly composed of casing, bottom frame, wear-resistant liner, shaftless screw body, K series gear motor, electro-hydraulic gate and electric control system.

For the length less than or equal to 8 meters, the conveyor is made of whole structure, and when it is more than 8 meters, it is made of segmented structure, with flange at the segmented place to be connected by bolt.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China