Our FPDJY-extruder is specially designed and manufactured for kitchen and food waste treatment system in environmental protection industry. Kitchen slag in the past are mostly directly into the slag collection and transportation vehicles to pull away for landfill or incineration, the shortcomings are: directly into the slag collection and transportation of solid slag still has a high water content, due to power plant incineration for slag water content has certain requirements, most of the existing slag is difficult to meet the requirements of the power plant can only be slag landfill, landfill disposal of environmental pollution is very high.

Our FPDJY-extruder is specially designed and manufactured for kitchen and food waste treatment system in environmental protection industry. Kitchen slag in the past are mostly directly into the slag collection and transportation vehicles to pull away for landfill or incineration, the shortcomings are: directly into the slag collection and transportation of solid slag still has a high water content, due to power plant incineration for slag water content has certain requirements, most of the existing slag is difficult to meet the requirements of the power plant can only be slag landfill, landfill disposal of environmental pollution is very high.

This equipment adopts PLC automatic control, without personnel guard, and effectively reduce the water content of slag, squeeze dry slag water content is completely lower than the requirements of the power plant, through the incineration of landfill to greatly reduce the environmental pollution caused by.

1、Characteristics

This equipment has good squeezing effect and relatively less loss of organic matter in solid residue. According to the use of experience, through comparison, the equipment in the industry in the performance of similar products is the most satisfactory. Specifically the following features:

(1) compact equipment structure, easy to install;

(2) Simple operation, smooth running, less vibration and noise;

(3) Good extrusion effect, long service life and low failure rate.

2. Basic performance parameters

|

Equipment Name |

Screw extruder |

Double screw extruder |

|||

|

Model |

FPDJY-650 |

FPDJY-600 |

FPDJY-350 |

FPDSJY-650 |

|

|

Processing capacity (t/h) |

15~20 |

8~12 |

3~8 |

10~15 |

|

|

Working air force(MPa) |

0.5-0.6 |

0.5-0.6 |

0.5-0.6 |

0.5-0.6 |

|

|

Slag water content (%) |

65-70 |

65-70 |

65-70 |

65-70 |

|

|

Extrusion form |

Spiral vane type |

Spiral vane type |

Spiral vane type |

Double spiral vane type |

|

|

Spiral diameter (mm) |

650 |

600 |

350 |

650 |

|

|

Screen type (mm) |

slit screen, clearance 3mm |

slit screen, clearance 3mm |

slit screen, clearance 3mm |

hole screen hole diameter 8mm

|

|

|

Transmission form |

Motor reducer direct drive |

Motor reducer direct drive |

Motor reducer direct drive |

Motor reducer direct drive |

|

|

Overall dimension (L×B×H) m |

6.3x2x2.1 |

5.5×1.6×2.2 |

3.5×1×1.3 |

4×1.95×1.95 |

|

|

Main material |

Main body |

Q235 |

|||

|

Sieve mesh |

SUS304 |

||||

|

Main shaft |

Q235 |

||||

|

Spiral blade |

16Mn |

||||

|

Power |

Input power |

37kw inverter |

30kw inverter |

15kw inverter |

22kw inverter |

|

Power supply |

380V 50HZ three-phase five-wire system |

||||

|

Noise (dB) |

≤70 |

||||

|

Weight of the whole machine (t) |

5.5 |

4 |

2.4 |

5 |

|

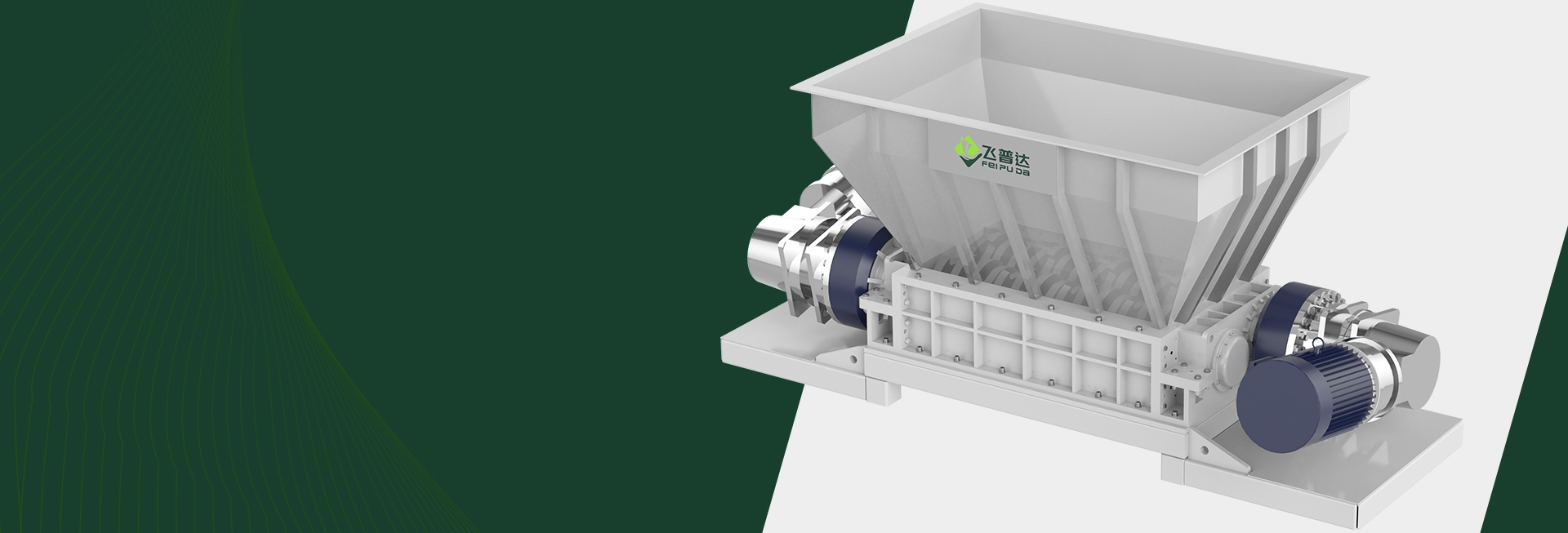

3、Structure

The extruder is mainly composed of base, screen, spiral spindle, motor, cylinder, body and other parts. Spiral extrusion dewatering machine technology is mature, long life, easy maintenance, this equipment is set up screen flushing measures, it is not easy to produce screen clogging phenomenon. The whole closed structure of the equipment can avoid the problem of malodorous gas pollution in the treatment process.

4、Working Principle

The motor drives the spiral spindle to rotate, the material is pushed forward by the blades, because the spindle adopts the way of variable diameter and distance, so the volume between the spiral blades decreases gradually from the import to the export, the material enters and pushes forward along the spiral blades to the export, the pressure gradually becomes bigger, so that the slurry in the material is extruded one after another, and the slurry flows through the sieve net into the storage box, and then enters into the next step of the processing process. This equipment adopts the cylinder propulsion method to keep pressure, the cylinder pushes the cone pressure plate to apply pressure inward, the thrust and position of the pressure cone is controlled by the cylinder.

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China