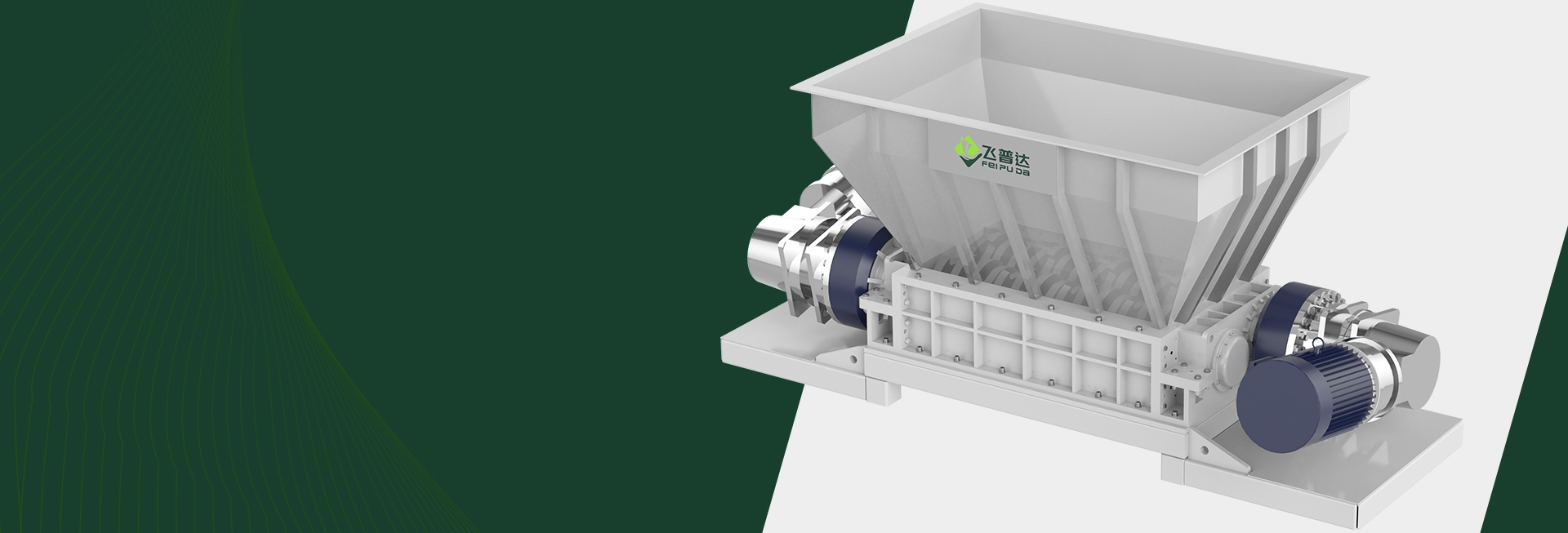

Double shaft integrated machine series are a new generation of special crushing and sorting equipment for kitchen waste, which are developed by our company on the basis of digesting, absorbing and introducing foreign technology, combining with domestic operation practice. It is suitable for domestic garbage crushing and screening, and is preferred to be used for crushing and screening of kitchen waste and other soft materials. This machine combines the functions of screening and purification together, and can be used to sort light materials while removing heavy impurities.

Double shaft integrated machine series are a new generation of special crushing and sorting equipment for kitchen waste, which are developed by our company on the basis of digesting, absorbing and introducing foreign technology, combining with domestic operation practice. It is suitable for domestic garbage crushing and screening, and is preferred to be used for crushing and screening of kitchen waste and other soft materials. This machine combines the functions of screening and purification together, and can be used to sort light materials while removing heavy impurities.

1、Equipment processing materials and working time

Kitchen waste pretreatment process: material reception + crushing and pulping sorting + sand and impurity removal + oil extraction.

Processed materials: kitchen waste (moisture content 80~85%), bulk density of about 700~800 kg/m³.

Designed capacity: 250 tons/day of kitchen waste;

2、Structural features

1) Rotating wear-resistant alloy hammerhead rotor, arranged sequence of circular sieve hole design structure, sedimentary outflow design, conducive to the discharge of heavy slag, the removal rate of its light impurities is better than the general crusher, to achieve a low energy consumption.

2) Fixed multi-section screen plate design, easy to replace, the rotor in the screen inside the good slurry area wear and tear is small, low maintenance.

3) The design of continuous light slag exclusion on the machine, parabolic slag discharge port is easy to discharge slag, and the water inlet valve, which can automatically adjust the given time of each action according to the cleanliness of the raw materials, effectively cleaning the cleanliness of the discharged waste slag.

4) Continuous discharge of light slag.

5) High output, not easy to clog.

3、Advantages

1) It can be more effective in crushing kitchen waste in the large hardness of the material, mild screening, clean light slag impurities, low energy consumption;

2) not easy to wear and tear, low maintenance costs;

3) high screening efficiency;

4) high production capacity;

5) high service life of sieve plate;

6) not easy to clog;

7) low requirements for incoming materials, strong adaptability.

4、Main technical parameters

|

Product Model

Item Unit |

FPDYT-800 |

||

|

Specification sieve plate |

mm |

∮800 |

|

|

Sieve hole |

mm |

∮20 (on request) |

|

|

Production capacity |

t/h |

15-20 |

|

|

Size of shaft inlet |

Inch |

1 Inch |

|

|

Feed concentration |

% |

≤15 |

|

|

Inlet size |

mm |

1042*633 |

|

|

Discharge hole size |

mm |

1042*600 |

|

|

Motor |

power |

KW |

2*75 |

|

Connection method |

/ |

Motor coupling direct connection |

|

|

Equipment weight |

T |

12 |

|

|

Overall dimension |

mm |

3390×3190×2900 |

|

|

Hammer head material |

/ |

Wear-resistant high chrome alloy |

|

|

Screen Material |

/ |

Wear-resistant high manganese alloy |

|

|

Body Material |

/ |

Carbon Steel |

|

Phone: 0086-13816616775

E-mail: sales@fpdgreen.com

Address: 140 Jinjiabang Street, Tanghui Street, Xiuzhou District, Jiaxing City, Zhejiang, China